|

|

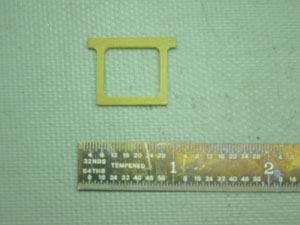

The connectors on the ccd package stick out a fair distance to the side, and will block part of the beam in the schmidt camera. So, we'd like to get rid of the connectors and the brackets that hold them in place. This is an engineering-grade chip that we were modifying.

|

|

The connectors are soldered into a small ceramic circuit board. On top of the ceramic board, there are contacts to wire-bond to the ccd. We'll want to keep the ceramic board, so we'll need to desolder the two connectors and go with a wire-bundle instead.

|

|

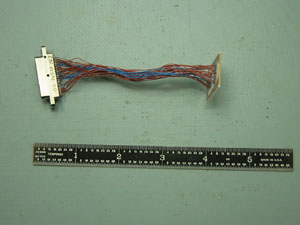

The wire bundle and spacer now attach to a 37-pin micro-D connector on one end, and to the ceramic circuit board on the other end. The wires are soldered into the holes left by the two connectors that were removed.

|

|

To protect the CCD, we melted paraffin wax onto the surface. We'll remove this later with a solvent.

|

|

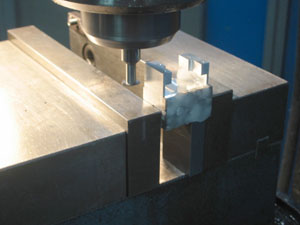

This is the ccd set up in the milling machine to remove the connector-mounting brackets.

|

|

And, the final slimmed-down package. We dissolved off the wax with acetone, mounted the ceramic circuit board and spacer with epoxy onto the side of the aluminum block.

There was quite a bit of difficulty re-bonding the ccd to the contacts on the top of the ceramic board. In the end, we re-tested the chip and it still worked.

The surface of the ccd was a bit mucked up by the wax. We decided not to proceed with modifications to the science chip.

Greg Burley (burley@obs.carnegiescience.edu)

Ian Thompson (ian@obs.carnegiescience.edu)