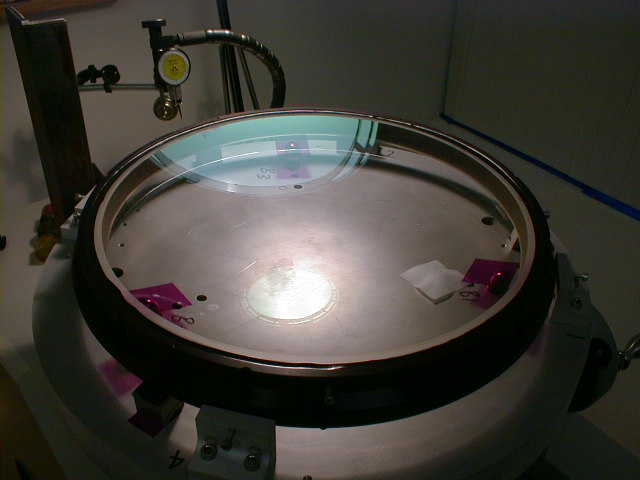

A view through the big glass...

The oil volume compensator and plumbing can be seen.

C02 after final back side pour of RTV 3112.

C02 after final front side pour of RTV 3112.

IMACS collimator element C02 and its cell are shown here on the assembly fixture. Location of the lens relative to the cell is established with the tooling balls, base plate, and a dial indicator. The lens and cell are concentric to about 12 microns (0.0005").

The lens assembly and RTV casting forms are checked prior to applying the adhesive.

An EFD adhesive dispenser is used to inject the RTV rubber into the gap between the lens and cell. OCIW Director Gus Oemler supervises the process.

The RTV can been seen in the gap following injection. The RTV starts to cure in about 45 minutes, and is fully cured after 24 hours. After curing, the lens and cell are removed from the tooling, the casting forms are stripped from the cell, and the assembly is ready for installation in the collimator barrel.

The collimator lenses are potted into their cells with RTV silicone

elastomer. In the foreground, a dummy lens has been potted into a reject

C02 lens cell.

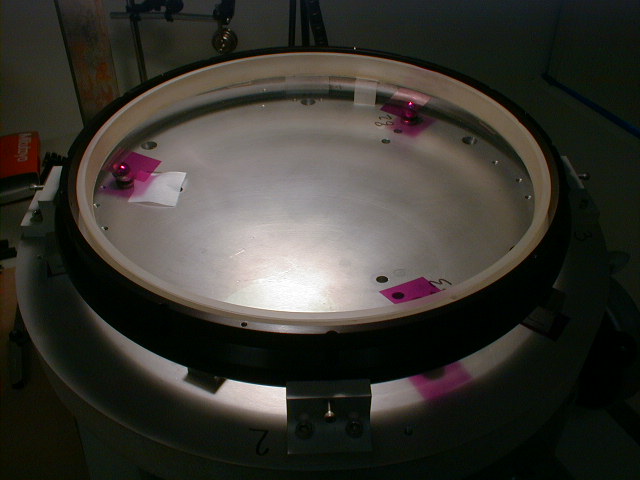

The rotary table is used to hold the lens, cell, and mounting plate. The lens sits on the tooling balls (properly protected), and the cell sits on the gauge blocks. Screws on the mounting brackets and cell are used to center the cell and lens respectively.