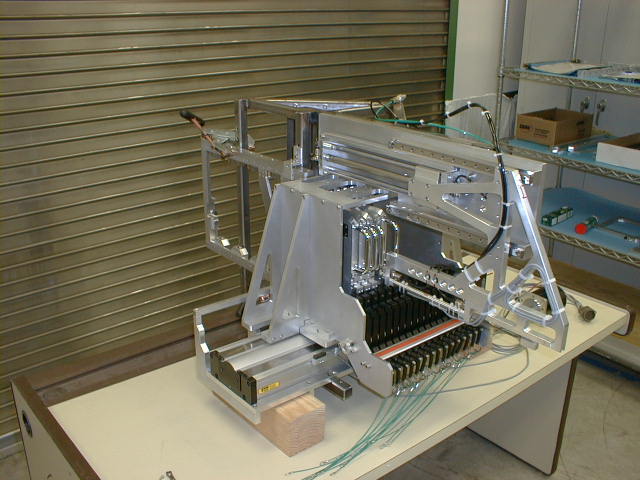

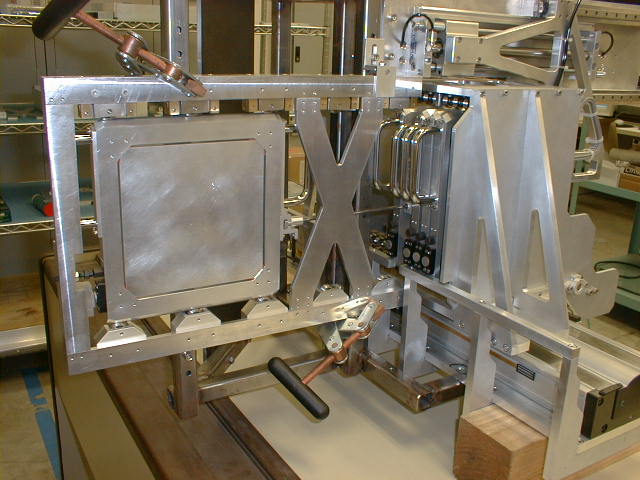

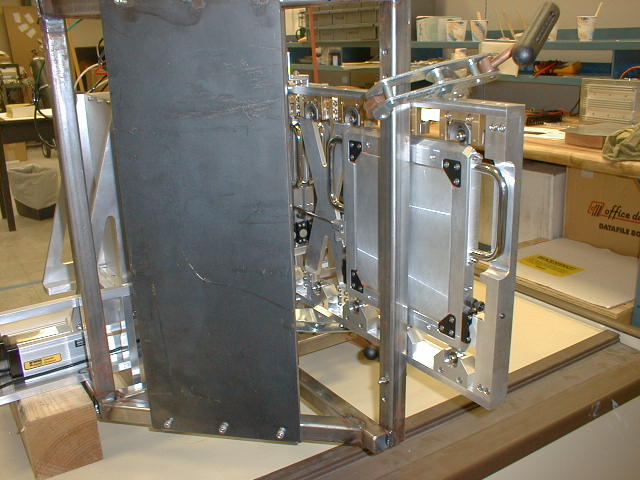

New filter insertion stages. Note the single-acting

air cylinder, reduced size of insert arm, and

rotationally symmetric key.

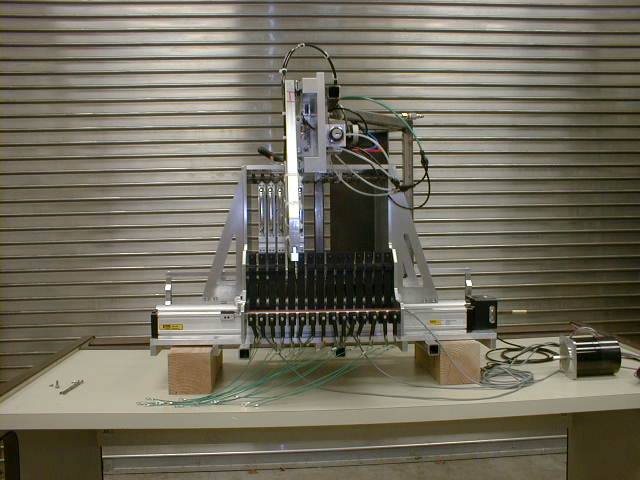

Old filter insertion mechanism. The two-stage insertion

arm, which includes a double-acting

air-cylinder, was revised to minimize space constraints,

and delete the rotationally sensitive

key mechanism.

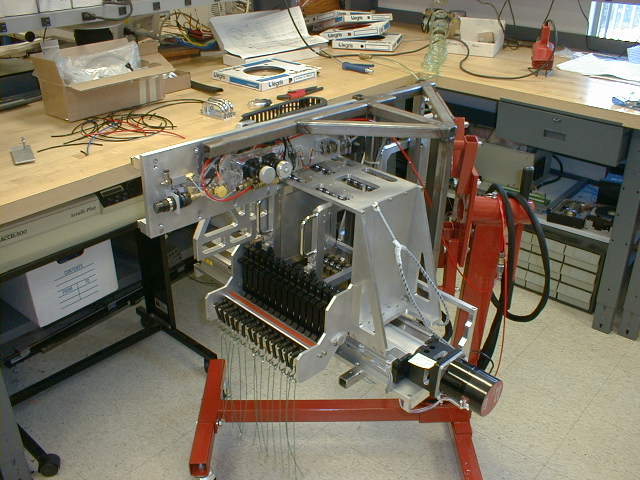

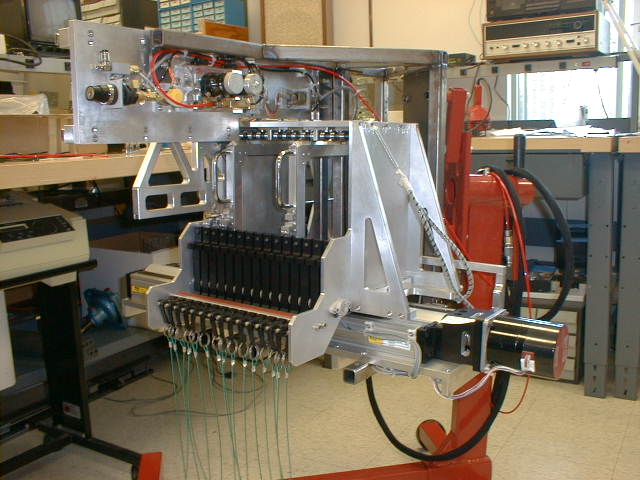

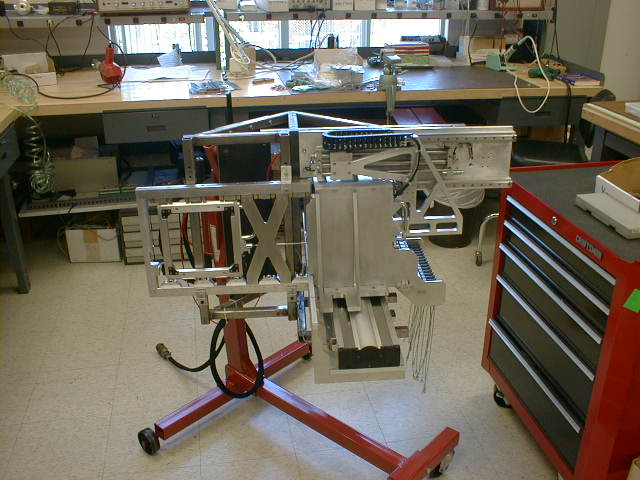

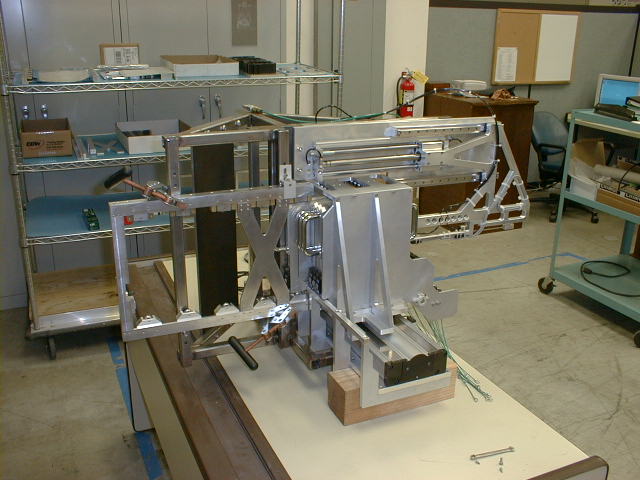

FSS is mounted on a red engine stand for testing.

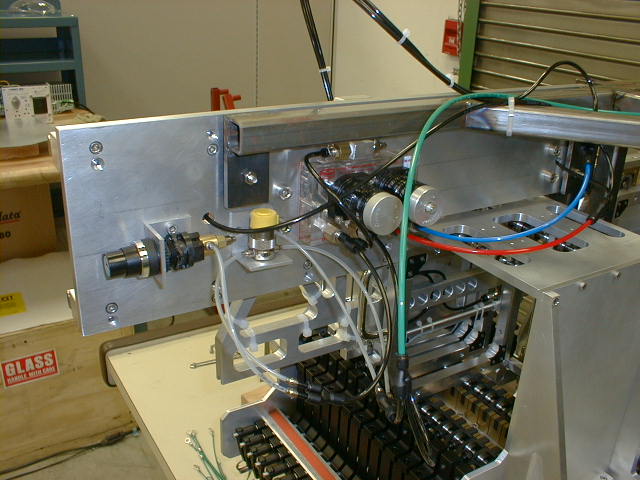

View showing fliter cassette, insertion arm, filters, and latches.

View showing the filter slide (image left), which will be inside the camera barrel.

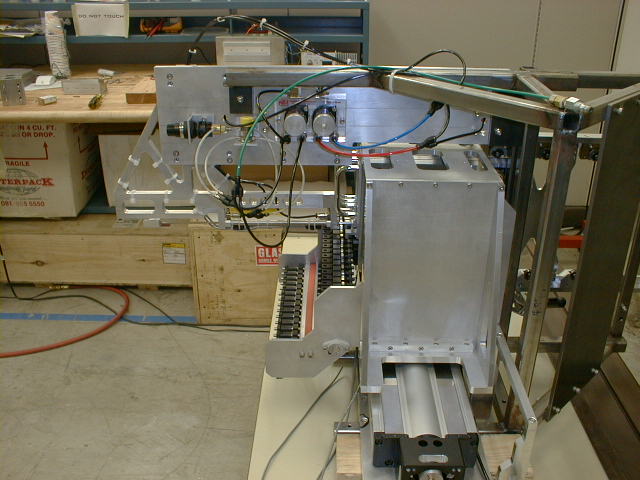

View showing prototype pnuematics, filter cassette, test fixture.

The cassette holds 15 150mm x 150mm filters.

The filter slide contains a filter frame and dummy (alum.) filter in the inserted position.

Dummy filter inserted.

Prototype pnuematics. This is the test configuration!

There are 60 of the spring-loaded guide wheel assemblies shown to the left.

There are 4 corner pieces per filter frame, or 80 total.