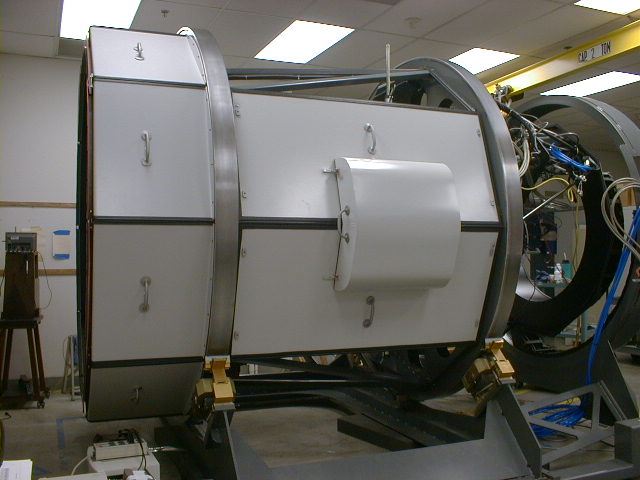

The dewar protrudes slightly out of the current enclosure

panels. An additional

cover for the dewar will be attached to the two adjacent

panels.

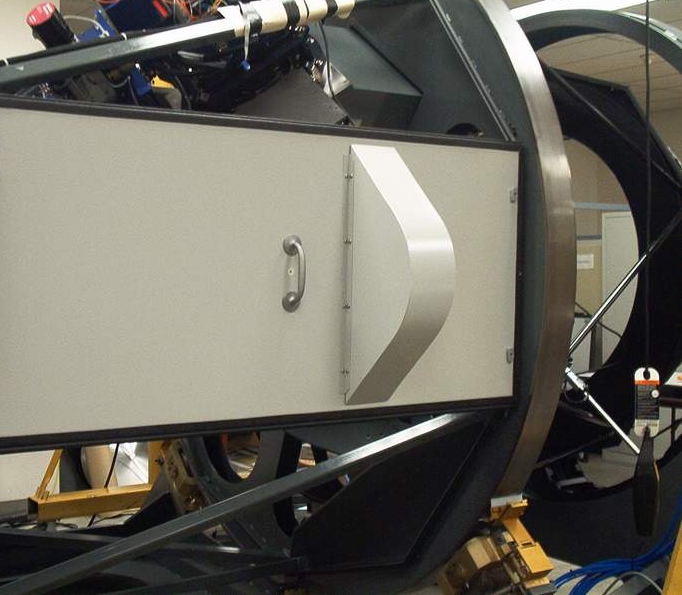

And like magic, a hole appears in two the central enclosure panels...

The new cover appears!

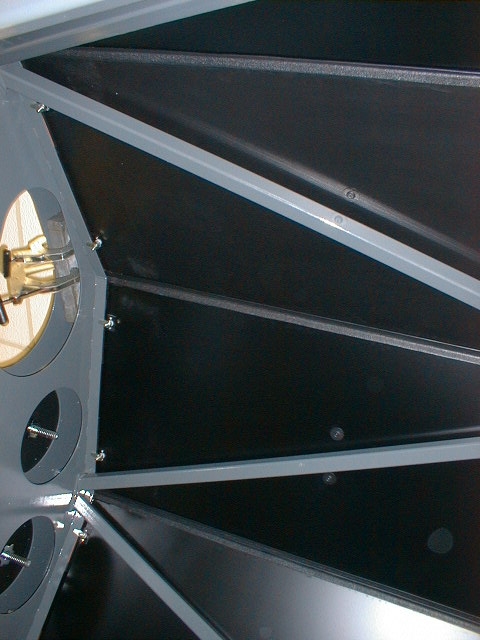

A typical cover (blister) for a shutter linear motor shaft

(there are 2 motors on each

shutter, and a shutter for each camera). Image

courtesy of Steve Gunnels.

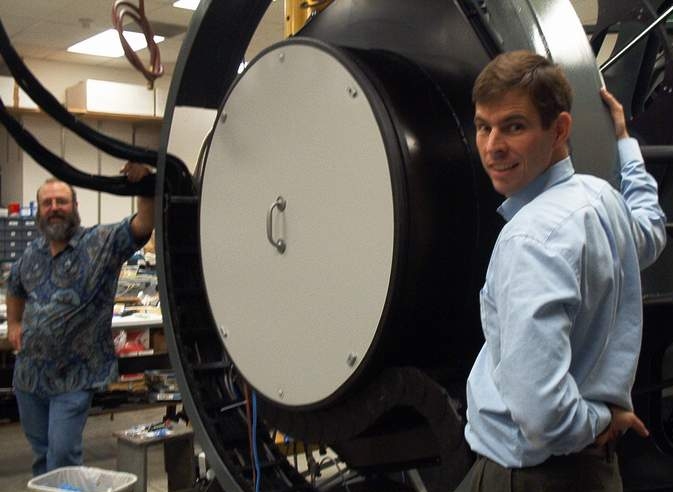

Bigelow and Baggish admire the short camera dewar cover.

Image courtesy of Steve

Gunnels.

Steve Gunnels and the IMACS enclosure panels installed

on the instrument. The large ring at the

far left of the structure is the fixed (non-rotating)

support structure for the IGUS utility wrap.

Side view of the IMACS enclosure panels installed on the

instrument. All that remains are the

small blister covers for the shutters and the long camera

dewar cover.

Valerie, Garrett, and Steve Gunnels unpack and arrange the enclosure panels prior to installation.

Panels ready to go.

Test fit-up of rear panels, which are not expected until early August.

Installing a middle panel is easier with two than one...

Inside view with half of the middle panels installed.

The quarter-turn latches can be seen holding the panels

to the lip on the structure.

Front and middle panels after assembly by the Paragon

Engineering crew.

7/8/02 - The hard-working panel builders at Paragon Engineering

- Valerie and Garrett

Gunnels.

7/8/02 - Front panels drying in the sun. The second

panel in this picture includes an opening

for changing slit masks.

7/8/02 - The slit mask access panel.

7/8/02 - A front panel with primer. The convex curve

attaches to the FOSS disk

of the instrument structure. The concave curve

seals against the altitude structure

of the telescope.

7/8/02 - Center panels bonded, stop corners reinforced

and ready for finish hardware.

Prepainted skins still have protective vinyl.

7/8/02 - Rear panels in process. Matte black interior surface is visible on two panels.